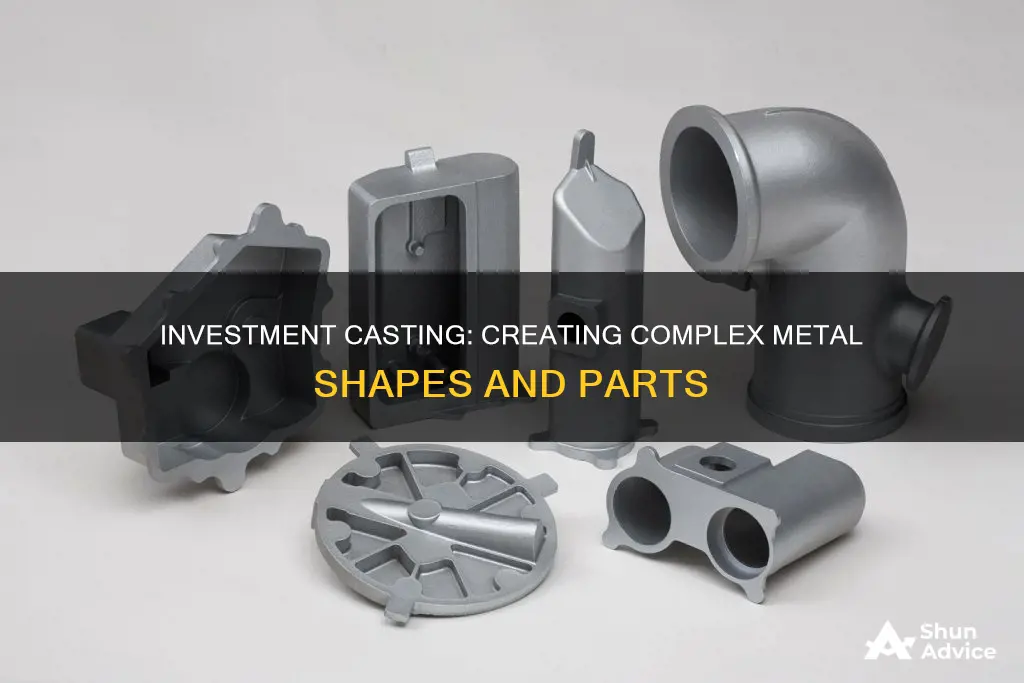

Investment casting, also known as precision casting or lost-wax casting, is a manufacturing process that uses a wax pattern to shape a disposable ceramic mould. The process is used to make small, precise metal components with complex internal passageways and thin walls. It is often chosen over other moulding methods because the resulting castings have fine details and excellent surface finishes.

The term 'investment' in investment casting comes from the Latin word 'investire', meaning 'to clothe'. The process was originally used for artistic craftsmanship such as jewellery and sculptures, but it has since been used to mass-produce metal and steel parts.

| Characteristics | Values |

|---|---|

| Used for | Small parts at large volumes, turbine blades, medical equipment, firearm components, gears, jewellery, golf club heads, machine components with complex geometry, decorations, religious figures, utensils, weapons, household goods, boat steering wheels, exercise/fitness equipment, fire hydrant components, firefighting equipment, street lamp bases and poles, snow plow components, cooling systems, armoured vehicle accessories, etc. |

| Process | A wax pattern is coated with a refractory ceramic material. Once the ceramic coating material is dry and hardened, the wax is melted out and leaves an internal cavity the shape of the final product’s geometry. Molten metal is poured into the cavity where the wax pattern was. The metal solidifies within the ceramic cavity, cools, and the ceramic is removed from the metal casting. |

| Precision | High dimensional accuracy, smooth surface finish, flash-free parting lines, ability to produce intricate parts |

| Metals used | Almost any metal, including stainless steel, aluminium, cobalt, carbon steel, brass, bronze, copper, nickel-based metals, beryllium copper, ductile iron, etc. |

| Cost | Can be more expensive than die casting or sand casting, but per-unit costs decrease with large volumes. |

Jewellery

Investment casting is a popular method for creating jewellery, particularly when intricate and complex designs are required. This technique, also known as lost-wax casting, has been used for thousands of years and remains prevalent in the industry due to its precision and ability to produce highly detailed pieces.

The process begins with the creation of a wax model, which can be hand-sculpted or made using 3D printing technology. This model is an exact replica of the intended jewellery piece, capturing all the intricate details and design elements. Multiple wax patterns are attached to a wax tree or sprue, which acts as a pathway for the molten metal to flow into the mould cavity.

The wax tree is then coated with a plaster or ceramic slurry, which is allowed to dry and forms a durable investment shell. This shell is then heated in a kiln or furnace, melting the wax and creating a hollow cavity in its place. The shell is further heated to remove any residual wax, moisture, and impurities, ensuring a clean and solid mould.

The prepared investment mould is placed in a vacuum or centrifugal casting machine. Molten metal, such as gold, silver, or platinum, is then poured or injected into the mould under pressure, filling the cavity and taking on the shape of the original wax pattern. Once the metal has cooled and solidified, the investment shell is broken away, revealing the metal casting.

The final step involves cleaning, polishing, and refining the casting to remove any imperfections, excess metal, or rough edges. This stage may also include additional processes such as stone setting, engraving, or plating to enhance the jewellery piece's appearance.

Investment casting offers several advantages for jewellery making. It allows for the creation of intricate and complex designs with excellent surface finishes and smooth textures. The process is compatible with a wide range of metals and alloys, providing versatility for jewellers. It also enables the accurate replication of jewellery designs, ensuring consistency in shape, size, and design elements across multiple castings. Additionally, investment casting can be cost-effective, minimising material waste and optimising production efficiency.

Personal Investment Plans: Your Guide to Financial Freedom

You may want to see also

Industrial components

Investment casting, also known as lost wax casting, is a manufacturing process that can be used to create industrial components. This process involves creating a wax pattern, which is then encased in a ceramic shell mould. The wax is melted out, leaving a cavity in the shape of the final product, and molten metal is poured into this cavity. Once the metal has cooled and solidified, the ceramic shell is removed, leaving behind the metal component.

Investment casting is particularly useful for creating industrial components with complex geometries, such as turbine blades, firearm components, and machinery parts. It offers excellent dimensional accuracy, even for intricate shapes, and smooth surface finishes. It is also compatible with a wide range of metals, including stainless steel, aluminium, nickel alloys, and cobalt alloys.

One of the key advantages of investment casting for industrial components is its ability to produce precise and intricate parts. This process can create components with thin walls, internal channels, and near-net shapes. It also minimises material waste and subsequent machining, as the casting is already very close to the desired final shape.

The versatility of investment casting allows for the production of a wide variety of industrial components. For example, it can be used to create engine and transmission components in the automotive industry, as well as gears, pumps, and valves in power generation and cooling systems. In the aerospace industry, investment casting is used for manufacturing turbine blades, impellers, and other aircraft parts.

In summary, investment casting is a valuable technique for creating industrial components, offering accuracy, versatility, and the ability to produce complex shapes with smooth surfaces. Its compatibility with various metals and its precision make it a preferred choice for manufacturing high-performance industrial parts.

Debt Instruments: Investing in India's Stable Options

You may want to see also

Turbine blades

Investment casting, also known as lost-wax casting, is a manufacturing process that has been used in various forms for thousands of years. It is a process that can produce precise components with intricate parts and smooth surfaces, all while minimizing material waste, energy use, and subsequent machining.

The investment casting process for turbine blades involves creating a wax pattern, which is then coated with a refractory ceramic material. Once the ceramic coating is dry and hardened, the wax is melted out, leaving an internal cavity in the shape of the final product's geometry. Molten metal is then poured into this cavity, where it solidifies and cools. The ceramic is then removed, resulting in a precision metal turbine blade.

Investment casting is particularly useful for creating turbine blades due to its ability to produce complex shapes and intricate designs. This process can accommodate undercuts and thru holes/passageways, which are often necessary for turbine blades. Additionally, the smooth surfaces obtained through investment casting can eliminate the need for secondary surface finishing and machining operations.

Overall, investment casting is a valuable technique for manufacturing turbine blades, as it offers precision, complexity, and efficiency in the production process.

Private Investment: When Planning Exceeds Saving

You may want to see also

Firearm components

Investment casting is a manufacturing process that can be used to make firearm components. This process, also known as lost-wax casting, is one of the oldest metal-forming techniques, dating back thousands of years. It is valued for its ability to produce components with accuracy, versatility, and integrity from a variety of metals and high-performance alloys.

- Triggers

- Hammer

- Sights

- Bolts

- Handles

- Stops

- Safeties

- Hinges

- Locks

- Mounts

- Housings

- Trigger guards

Investment casting is ideal for firearm components because it offers design freedom and the ability to incorporate intricate details. This process can produce high-strength, precision components with exceptional surface qualities, reducing the need for secondary machining processes.

The use of investment casting in firearm manufacturing also provides shorter lead times, reduces waste, and requires only tight tolerances for secondary machining, making it a cost-competitive and efficient alternative to traditional CNC production methods.

Investment Management Law: Understanding the Basics

You may want to see also

Golf club heads

Investment casting is a manufacturing process used to make golf club heads. The process involves creating a wax pattern, which is an exact replica of the final product, and using this to produce a ceramic mould. The mould is then filled with molten metal to create the club head.

The process is popular because it allows for the creation of highly intricate and complex shapes with virtually any alloy. It also produces excellent dimensional accuracy and a fine surface finish, reducing the need for secondary machining.

Before a golf club head is put into production, it is designed on a computer using CAD software. This design is then used as the basis for the development of a proprietary mould, which is used in the production of each and every club head. The mould is a mirror image of the club head and has two parts to it, with a small opening on the side.

The wax pattern is manufactured using a specially created wax injection tool and is then attached to a tree-like assembly. It is then coated in a liquid ceramic slurry before being dried in environmentally controlled conditions. The ceramic shell is then fired at a high temperature to harden the material, a process that doubles its mechanical strength. While still hot, the shell is filled with molten metal, which then cools and solidifies. The club heads are then cut off the tree by a metal cutter and the finishing process begins.

Investment casting is a popular method for manufacturing golf club heads as it allows for the creation of intricate and complex shapes. It also produces excellent dimensional accuracy and a fine surface finish, reducing the need for secondary machining. The process is also versatile and can be used with a wide range of alloys.

Building a Solid Investment Portfolio: A Beginner's Guide

You may want to see also